The Idaho Transportation Department (ITD) utilizes several types of concrete barriers. For permanent installations Idaho typically calls for slip formed or cast-in-place concrete barriers that do not require connecting or stabilization pins. However, Idaho also utilizes 10’ and 20’ precast concrete barriers that do require connecting and stabilization pins. Connection pins can either be fabricated, one-piece, or an alternate design as detailed below. Stabilization pins come in one of two different configurations, depending on what type of surface the barriers are being anchored to. Connection pins are not required to be galvanized, while stabilization pins are required to be galvanized. All of the details can be found in the Idaho Standard Drawings.

Connecting Pin – PB Part #18249

Connecting Pin – PB Part #18249

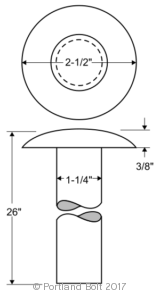

For connecting 10’ and 20’ precast concrete barriers, Idaho has three different options for the connecting pins. The first option is a fabricated connecting pin that is made by welding a 3/8″ thick by 2-1/2″ diameter plate washer to a 1-1/4″ diameter by 26″ long piece of ASTM A36 steel round bar. Option two is the same design but as a one-piece forged head, rather than as a plate welded to a rod. The third option is an alternate connection pin that is manufactured by threading one end of a 1-1/4″ x 40″ A36 rod, assembling a nut and two washers on the end, and then tack welding the nut to the rod. All three options are plain steel and are not required to be galvanized. There is also a forth style of connecting pin that is utilized with some limited use types of concrete barrier. These limited use connecting pins are made from 1″ x 29″ A36 rods with a 2″ diameter washer welded on one end. The fabricated, one-piece head, and alternate design connecting pins can be seen on Idaho Standard Drawings G-2-A-1, G-2-A-2, G-2-C, G-2-D, and G-2-I-1. The limited use connecting pins can be seen on Idaho Standard Drawing G-2-A.

Stabilization Pin – PB Part #18248

Stabilization Pin – PB Part #18248

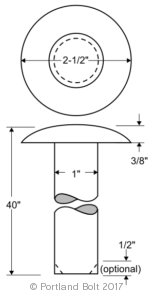

For anchoring precast barrier sections in place Idaho utilizes two different types of stabilization pins. For anchoring barriers to bridge decks, a 7/8″ diameter galvanized high strength ASTM A325 rod assembly with plates, nuts, and lock washers is utilized. The length of the bridge deck stabilization pin varies depending on the thickness of the bridge deck. For concrete or asphalt anchoring, a 1″ x 40″ long ASTM A36 steel round bar with a 3/8″ thick x 2-1/2″-3″ diameter round plate washer welded near one end is used. The other end may be given an optional bevel to facilitate placement. The entire stabilization pin assembly is required to be hot dip galvanized after fabrication and welding. Per Note D on the standard drawings, a one piece stabilization pin with a 2-1/2” rounded top may be used in place of the rod with a welded round plate (shown). The details of the stabilization pin can be seen on Idaho Standard Drawings G-2-A-1, G-2-A-2, and G-2-D.